element in material science?

Our spirit.

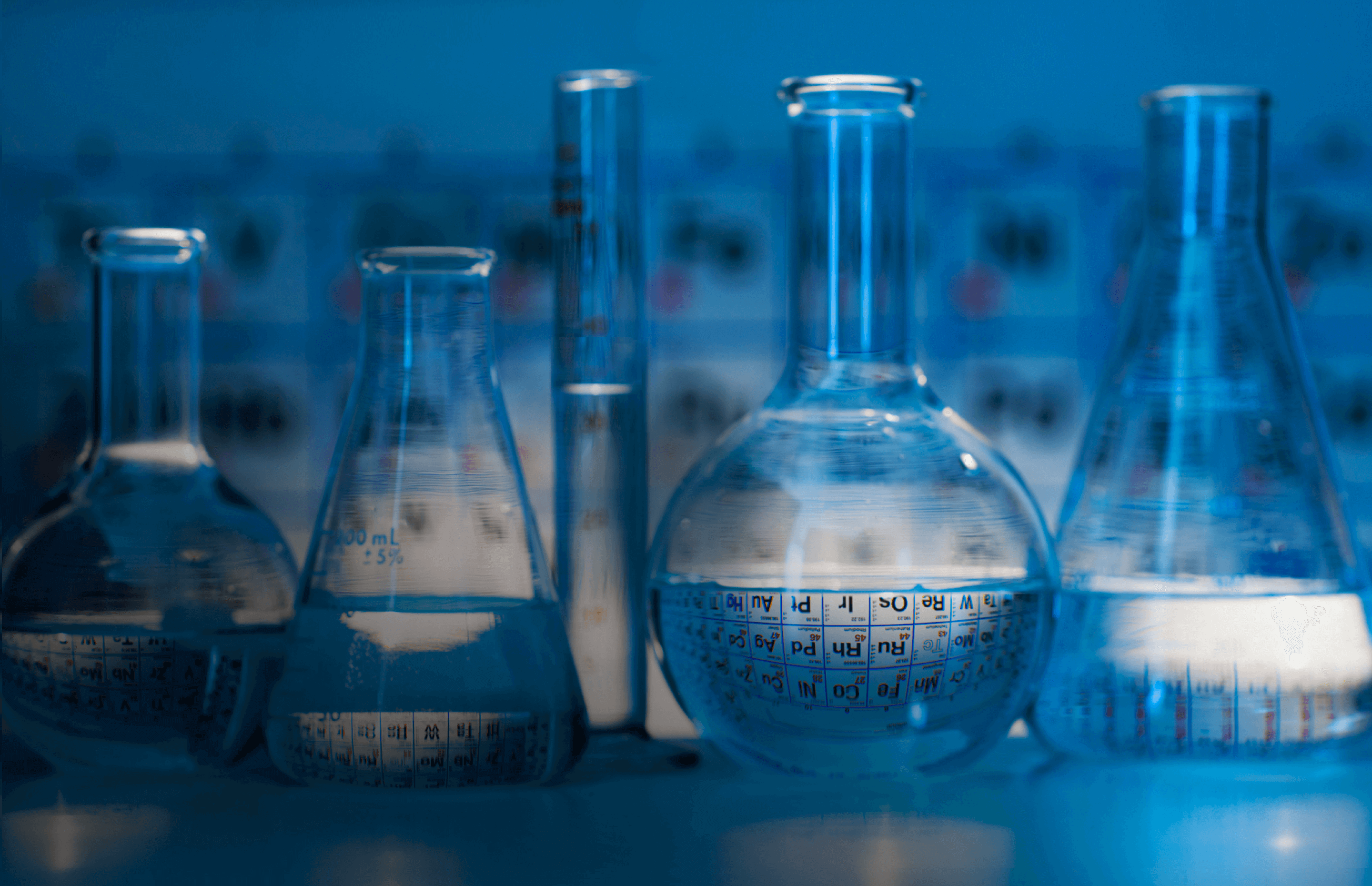

Exposure to the elements

Telecommunications equipment is constantly exposed to the weather and material science is key to its durability. In response to a customer review about a minor blistering of an aluminum surface on a Huawei product, Dr. Hu, with 30 years of material science experience, decided to improve on it.

Material investigation team

To find answers to resisting corrosion and weathering, Dr. Hu mobilized a team of scientists at Huawei’s Materials Laboratory to research the effects of harsh environments on materials. The team went around the world to investigate real-world scenarios.

Hot to cold

From the freezing temperatures of Siberia, Russia, to the unbearable heat of the Sahara and Nigeria, materials were tested against Earth’s natural extremes.

Humid to dry

From the 90% humidity of Singapore’s natural environment, to the dry regions of Peru, material scientists experimented with the equatorial to the exotic.

Pollution, exhaust and droppings

Analysis was done against the backdrop of condensation, air-conditioner exhausts, chemical plant runoffs, and even bird droppings and insect remnants.

2,000 base stations, 30 countries and 2 years later, research data was accumulated to see if aluminum could be made more durable against the weather. Dr. Hu spent the next 3 months at a foundry–where temperatures can reach 50˚C–to test and adjust the aluminum alloy ratios as close as possible to perfection. It took 11 months and over 200 test pieces before the ideal aluminum alloy ratio was found. The newly created aluminum alloy offers 4 times better corrosion resistance, and 30% improved heat dissipation properties. Dr. Hu’s global research and testing efforts had paid off.